Custom Robot & Robotics Cases

Shop By Categories

- Custom Aerospace Shipping Cases

- Aerospace Cases With Electric Lifts and Ramps

- Custom Shipping Cases

- Custom Medical Equipment Shipping Cases

- Ramp Shipping Cases

- Custom Robot & Robotics Cases

- Custom ATA Flight & Road Case Solutions

- Custom Foam Interiors

- Custom Trade Show and Exhibit Shipping Cases

- Shipping Cases With Electric Lifts and Ramps

- Lab Equipment Shipping Cases

- Custom Aerospace Shipping Cases

- Electric Lift & Ramp Cases

- Ramp Cases

We design custom shipping case solutions that will deliver robotic devices safely and simply. We also offer FEA analysis when you require your custom shipping case solution to be validated to your specific criteria. Our virtual simulation analysis services – SIMLab-WCi will validate our shipping case solutions and reduce or even eliminate the need for physical prototypes and testing. Say goodbye to the tedious and costly design-build-test-redesign stage of getting your product safely on the road. We offer drop-impact, proof load, static linear, thermal and vibration analysis.

LEARN MORE about our FEA service SIMLab WCi

Showing all 2 results

When you’ve dedicated significant money and resources to developing a robot or robotic system, the last thing you want to worry about is having your machine damaged in transit. Unfortunately, transporting your robots or computers can be a risky endeavor if you aren’t armed with high-quality shipping crates. If your robotics shipping crate can’t stand up to rough handling, you could end up damaging delicate and expensive components, such as sensors, motors, LCDs, or microcontrollers.

Make sure your robotics shipping case is up to the task of protecting fragile equipment: order a custom robot crate from Wilson Case. We have experience designing tough shipping cases for everything from surgical to telepresence robots. You can browse some of the cases we’ve built and request a similar design or work with us to design a custom robot case from the ground up.

Why Choose Wilson Case for Robotics Shipping Cases?

We’ve been designing custom shipping cases for over 30 years and have built robot crates for clients such as Medtech Surgical, Concept Systems, and MagneMotion. We understand the biggest challenges you face when you need to ship a robot, and we address those challenges in our design process.

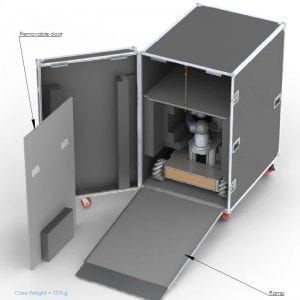

For example, we can add a ramp and guide rails to your case to make it easier to load and unload a large and heavy robot. We can develop a case with foam-lined compartments—including a compartment for a heavy battery—when you need to protect your robot’s sensitive components. If you’ll be transporting robots from a warehouse, we can add our RamGuard plates to your case to prevent accidental forklift damage.

We don’t believe in “one size fits all” at Wilson Case, and we don’t take shortcuts when it comes to designing your robotics shipping case. We’ll make sure we fully understand your cargo and shipping challenges so that we can provide a case with all the features necessary to make transporting robots simple.

How We Design and Construct Robot Cases

To start our design process, we’ll talk to you about the robot you need to ship, and the case features you anticipate needing. We’ll then ask you to send us a blueprint-like file for your robot so that we can tailor the case to its cargo, without you having to send the actual robot to us. From there, we’ll use SolidWorks, a 3D CAD program, to design the case. We’ll send the finalized design file, which lets you see detailed renderings of your robot crate, to you for approval.

With your approval, we’ll start fabricating your robot case in our workshop. All cases are assembled by our skilled manufacturing team, using technology that allows us to cut materials with accuracy to the thousandth of an inch. We’re so confident in the quality of our custom-made robot crates that we offer a lifetime warranty.

Order Custom Cases, Start Transporting Your Robots Securely

When it’s time to ship your robot, or any computer components, a cheap box won’t cut it. Wilson Case will design a case with the high-quality materials and features necessary to protect your advanced machinery. To get a quote today, call us at 800-322-5493 or fill out our short online form.