Clamp On Lid - Front Load Shipping Cases

Shop By Categories

- Custom Aerospace Shipping Cases

- Drone & Antenna Shipping Cases

- Large Shipping Cases

- Miscellaneous Shipping Cases

- Tooling, Spare Parts, and Calibration Cases

- Custom Shipping Cases

- Custom HDTV/LCD/LED/VIDEO WALL Shipping Cases

- Custom Medical Equipment Shipping Cases

- Ramp Shipping Cases

- Custom Simulator Shipping Cases

- Custom Robot & Robotics Cases

- Custom ATA Flight & Road Case Solutions

- Custom Foam Interiors

- Custom Computer Shipping Cases & Custom PC Cases

- Custom Trade Show and Exhibit Shipping Cases

- HDTV, Monitor, and Video Wall Shipping Cases

- Shipping Cases With Electric Lifts and Ramps

- Trade Show Booth, Product, and Misc. Cases

- Work Cases. Tables & Drawers

- Custom Kiosk Shipping Cases

- Mobile Training Shipping Cases

- Lab Equipment Shipping Cases

- Custom Drone Carrying and Travel Hard Cases

- Custom Aerospace Shipping Cases

- Drone & Antenna Shipping Cases

- Miscellaneous Shipping Cases

- Tooling / Spare Parts / Calibration Cases

- Custom Government / Military Shipping Cases

- Clamp On Lid - Front Load Shipping Cases

- Medical Cart Shipping Cases

- Ramp Cases

- Wilson Case Aerospace Custom Shipping Cases

Wilson Case manufactures a wide range of containers to meet the shipping needs of many industries, including the healthcare, aerospace, athletic, entertainment, tech fields and more. If you are unable to find exactly what you’re looking for in our catalog of stock shipping cases, we also offer custom cases that are built to your exact specifications.

We work closely with our customers to design custom shipping cases that address their specific packaging pain points while remaining conscious of their budget and important deadlines. We like a challenge and we’ve manufactured innovative cases to safely transport all kinds of fragile, heavy, and/or expensive equipment. We’ve made custom travel cases that have built-in work areas for professionals who require a mobile workstation, and we’ve even manufactured a mobile lift to raise a bulky medical device out of its hard case. All of our cases are designed to be simple to safely load, ship, unload and repeat.

We let our customers dictate not just the dimensions of their custom shipping case, but also the laminate color, interior lining, labeling, security features, and mobility and stacking options. We also offer an extensive selection of add-on features, including pull-out keyboards, trap doors, ramps, and pressure relief valves. Any case that you can imagine, we can build.

Browse some of our previous custom designs below:

Showing all 16 results

-

#39-3240 Custom Drone Shipping Case

Read more -

#39-4301 Hand Washing Stations / Kiosks Case

Read more -

#40-1221 Aircraft Parts Shipping Case

Read more -

#40-1222 Aircraft Parts Shipping Case

Read more -

#40-1223 Aircraft Parts Shipping Case

Read more -

#40-1224 Aircraft Parts Shipping Case

Read more -

#40-1280 Aerospace Shipping Case

Read more -

#56-966 Custom Shipping Case

Read more -

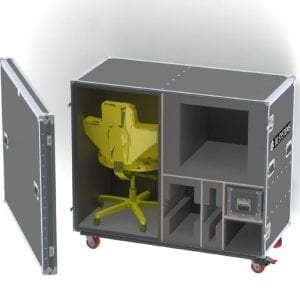

#39-2917 Custom Work Box

Read more -

#39-3406 AV Table Shipping Case

Read more -

#39-3377 Custom Robotix Accessories Case

Read more -

#39-2717 Custom ATA-300 Shipping Case with Custom Foam

Read more -

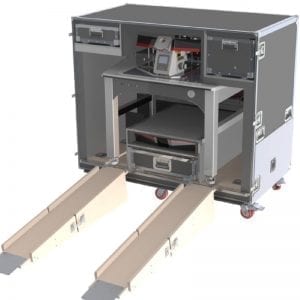

#70-466 Custom Shipping Case w/ Ramp

Read more -

#88-2612 Compartments Custom Shipping Case

Read more -

#70-591 Custom Medical Device Shipping Case

Read more -

#44-2931 Custom Ramp Cases

Read more

How Our Custom Design Process Works

We start by talking with our customer to determine what type of case they are looking for and what particular challenges (such as heavy equipment or frequent travel) they are facing. During our conversation, we also look for issues the customer may not have considered, such as whether the case will fit through a standard door or meet airline requirements for checked bags.

After deciding on a design, we have our customer send us a file with the dimensions of their equipment, much like a blueprint, that we can use to design their shipping case. While many shipping container manufacturers need access to the equipment itself in order to build a case, we are able to fabricate our custom hard cases without ever having to see what will go inside them.

Once we have the product dimensions, our engineers use the SolidWorks 3D CAD program to model the case. We are then able to send a detailed 3D presentation to our customer so that they can see exactly what their case will look like, down to the placement of the handles and holes.

When a design is approved, we take the same files we presented to the customer and convert them to CNC computer control language, which allows us to cut the case materials on our machines, with precision down to the thousandths of an inch. We use only the highest quality materials in building our cases, because we know that many of our customers travel frequently and need a container that can handle heavy use.

Order Your Custom Equipment Case Now

Whether you need to move sensitive medical devices, expensive sound equipment, or any other valuable products, Wilson Case can design a protective case that makes transporting your gear a whole lot easier. Contact Wilson Case today to get your quote and learn more about how we can design a custom case for your specific shipping needs.