Types of Foam Used for Custom Foam Case Inserts

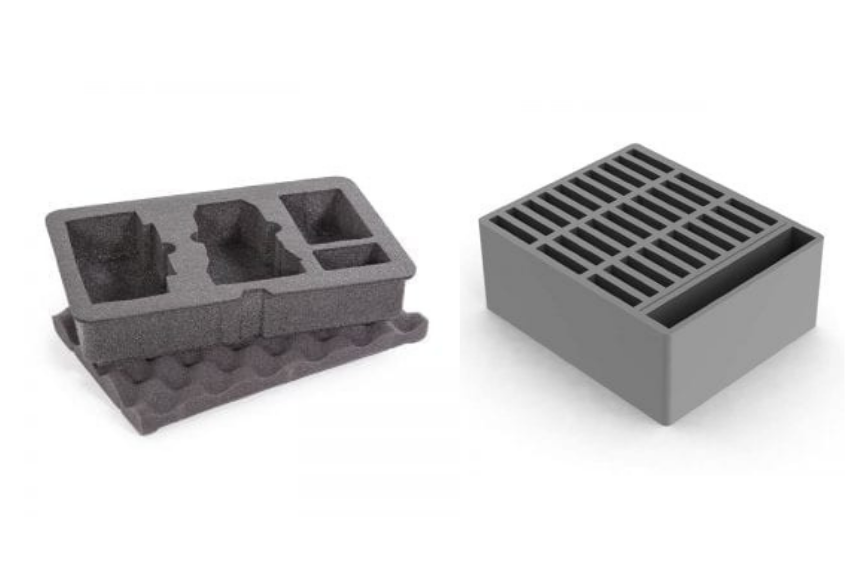

In addition to designing custom shipping cases for an endless variety of industries and shipping challenges, Wilson Case also customizes the foam inserts that can go inside cases. Our custom packing foam can be cut, sculpted, and configured to fit any cargo, making sure your valuable items have protection both inside and outside their shipping case while they’re in transit.

Just as there is a different shipping case for every situation, there are also different types of foam. Our team of experts will make sure your case has exactly the right kind of packing foam material for your next shipment. Learn more about our custom foam inserts for boxes and hard cases and the types of foam we use to make them.

Foam Types

Wilson Case uses three main types of packing foam for our custom foam case inserts, each with different attributes and advantages.

- Polyethylene foam: A closed-cell type of foam that is more rigid and firm than our other foam types. Polyethylene is the best choice for shipping heavy items. It’s also our default option for lining multipurpose cases with 1/2” of foam.

- Polyester foam: A soft foam for protecting more sensitive shipments. This is the best option for items that are particularly fragile.

- Antistatic foam: This type of foam is specifically used for transporting sensitive electronic components safely. You can recognize antistatic foam by its pink color.

How We Produce Foam Case Inserts

Once we’ve identified the right type of foam for your requirements, we’ll use a few different machine cutting techniques to create and fine-tune your custom hard case foam inserts. With computer-controlled routing (CNC), we can precisely cut and shape packing foam and other materials to fit any object snugly. Our environmentally friendly water-jet cutting solution uses a high-pressure jet stream to cut with smooth and accurate edges.

Trust Wilson Case for Your Custom Foam Case Inserts

Whatever you need to ship, no matter how big, small, sturdy, or delicate, we’ll select the right type of packing foam and carefully mold it to make sure your items arrive in one piece and fully functional. You can count on Wilson Case to create your custom case inserts with the same level of skill and dedication we apply to our shipping cases themselves.