FEA Thermal Analysis on Wilson Shipping Case Solutions

Our virtual FEA analysis gives you the power to ensure that your product is not just in a good shipping case, it's in the best!

SIMLab-WCi thermal analysis is a method that enables you to assess the heat transfer over components due to thermal loads. This analysis method yields a comprehensive steady-state and transient behavior of your product subjected to thermal environments. It uses thermal variables and boundary conditions which are related to the displacement and stress predict your model’s structural response due to the thermal conditions.

This analysis can help you identify potential thermal failure points, optimize the design of your shipping case, improve the reliability and durability of your product, comply with regulatory requirements and save you time and money. Virtual FEA analysis removes the constraints of limited iterations, and the design, build, test, repeat system that your competitors are doing to get their products on the road.

SIMLab-WCi Virtual FEA Analysis allows us to validate our shipping case in the design phase. It allows you to reiterate the shipping case design till we get it right, before we build it.

SIMLab-WCi Thermal Step analysis consists of:

- Evaluate temperature response

- Heat flux vectors

- Structural Step Analysis

SIMLab-WCi Thermal Stress analysis consists of:

- Displacement

- Stresses

- Factor of safety

Ready to find out more about SIMLab-WCi?

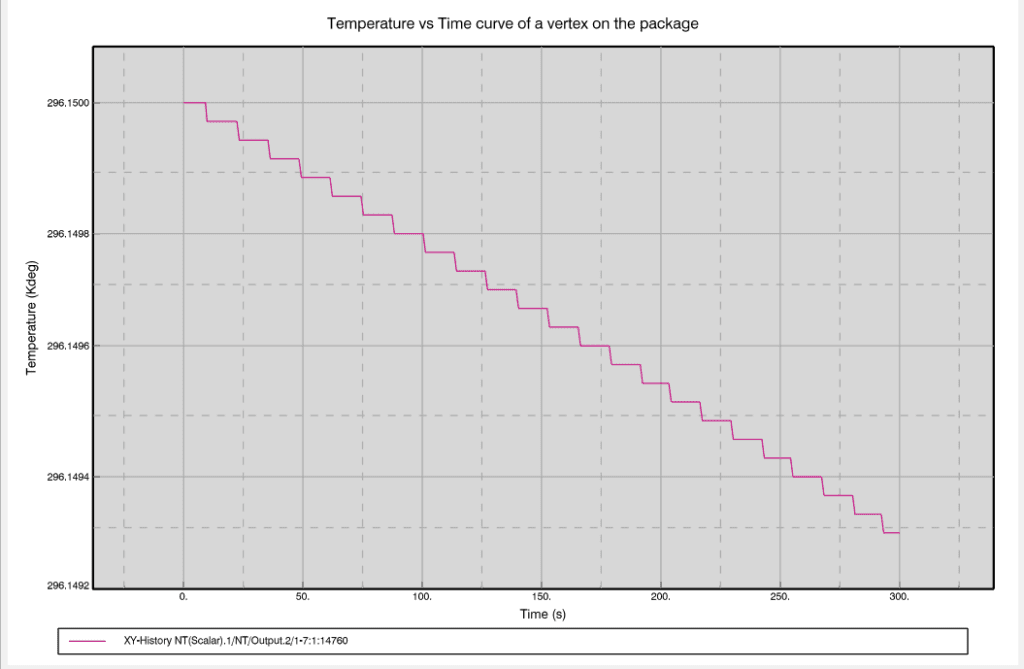

In the animation above, we can see how the temperature is being distributed across the entire model. The shipping case contains a unit that is being cooled down by an icepack. The analysis was set to a transient thermal analysis and the total simulation time was set to 5 minutes. An initial temperature was set for the icepack and the part being cooled down. Then, a room temperature of about 75 degrees Fahrenheit was specified for the internal faces of the panels and the lateral sides of the inside unit. The outer faces of the case are exposed to an ambient temperature of 75 degrees. After the analysis has completed, we can plot the thermal field information at any of the time steps. In this analysis, we observed that the icepack is doing a great job in cooling down the part since for this estimated overall solution time of 300 seconds we have noticed that the value of the temperature of one of the corner vertices of the part has dropped down.

You do not need to know ahead what will be the effect of these thermal loads while your package is in transit. We can figure it out for you.